Lean Engineer

He is responsible to oversee and reduce and production errors. Our engineers re-think everyday products to remove unnecessary components.

House Of Lean In 2021 Industrial Engineering Lean Manufacturing Key Performance Indicators

Five Key Principles The Lean Enterprise Institute LEI founded by James P.

Lean engineer. Email field should not be empty Please enter a valid email. LEAN Engineering techniques are the ideal roadmap to achieve turn a company into competitive and of excellence within the current market. Activities include providing cross-functional support throughout the entire organization developing and completing A3s and linking project metrics to site strategic objectives.

Lean Engineer jobs Enter your email address to receive alerts when we have new listings available for Lean Engineer jobs. Wilson Sporting Goods Co. Lean engineering practices work to improve the efficiency and efficacy of engineering departments within manufacturing organizations.

This is an excellent opportunity for someone who enjoys Lean Thinking. The term Lean was coined in 1988 by John Krafcik and defined in 1996 by James Womack and Daniel Jones to consist of five key principles. 39 Sparta TN 38583 In this role you will establish implement and maintain formal manufacturing systems and processes in support of Lean Manufacturing and Continuous Improvement.

He is also responsible for designing and planning the production operation process. We are looking to hire a Lean Engineer to help support our Warehouse Operations and work on Continuous Improvement Projects. Lean Engineering is a continuous improvement process designed to increase the efficiency and horsepower of engineering departments within manufacturing companies to make them more competitive in their marketplace.

414 likes 2 talking about this. He is also responsible to make production operations error free to avoid wastage. Lean engineers are an essential part of developing successful software products particularly in companies with non-trivial technical constraints and product complexity.

LEAN is a cultural change in the business organization with a High. Lean Engineering is a continuous improvement process designed to increase the efficiency and horsepower of engineering departments within manufacturing companies to make them more competitive in their marketplace. Bilgi Değer Katar.

Lean engineering can help organizations become more innovative and competitive while saving money and optimizing resource efficiency. A lean manufacturing Engineer is responsible for manufacturing operations work. New Wilson Sporting Goods Co.

Save job Not interested Report job Save job More. Jones in 1997 is considered the go-to resource for lean wisdom training and seminars. It meant we could eliminate blades that chop the air and the protective grilles that surrounded them.

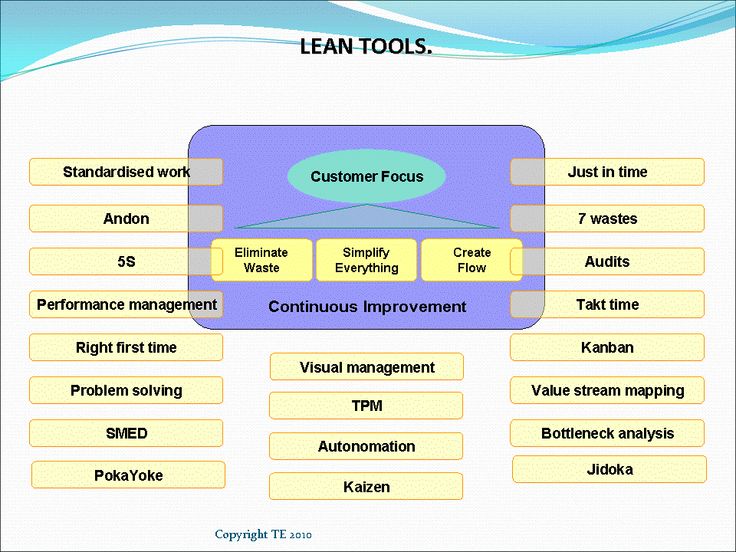

LEAN is a system with many dimensions that affects especially the elimination of the waste by applying the techniques that will be described in this article. Lean Engineer65-110KWaterloo IowaOur client is seeking a Lean Engineer for their Waterloo Iowa locationi This employee is responsible for executing continuous improvement projects to reduce overall manufacturing costs throughout the facilitiesi This will include cycle time improvements plant layout changes capital equipment proposals robotic cell layouts fixturejig improvements and. Driving EHS and Regulatory alignment with the support of the plant Safety organization 2 days ago.

- Materials Process Engineer SPECIAL PROCESSES Tube-Fab Ltd 19. Value value stream flow pull and perfection. The Lean Engineer will be responsible for preparing facilitating and following up continuous improvement Kaizen Events supporting the planning development and execution of Lean strategies culture and metrics.

65000 - 80000 a. Being the key contact for a family of products within the Tape Plant. Lean Value Stream Engineer new.

Türkiye nin en iddalı video eğitim kişisel gelişim bilim ve teknoloji platformuna hoşgeldiniz. Womack and Daniel T. By harnessing a phenomenon called the Coandă effect they revolutionized the personal fan.

According to Womack and Jones there are five key lean principles. They take the time to appreciate how the business works how the product fits in and what its goals are. Structure of the LEAN system.

Precisely specify value by specific product identify the value stream for each product make value flow without interruptions let customer pull value from the producer and pursue perfection Womack and Jones 1996 p10. 39 Sparta TN 38583 We are looking for a candidate with a minimum of 5 years of strong experience in manufacturing engineering.

How To Become A Lean Manufacturing Consultant Lean Manufacturing Visual Management Lean Sigma

5 Lean Principles Every Engineer Should Know Digital Marketing Information Technology Cyber Security

Safe Principles Of Lean Agile Leadership Train Engineer Agile Lean Enterprise

House Of Lean Diagram Foundation Sets Lean Manufacturing Kanban